Pressure-suction rubber hoses are used in many fields of industry for liquid transfer, fuel transfer, petroleum-based oil transfer and also in other industries. By the structure, it is not a usual rubber hose, it has an inside layer and an interlayer made of rubber, rubberized fabric gaskets, metal spiral that allows the suction hose to do its main function – to transfer (to pump) different liquids. Different models can operate for pressurization at the pressure up to 0.5 MPa and bare the vacuum up to 0.08 MPa.

Types of pressure-suction hoses GOST 5398-76 by the arrangement

-

“W” - for technical water injection

-

“G” - for gasoline, cerrosine, diesel fuel

-

“AA” - for transfer of acids and alkaline of 20% concentration

The operating temperature of hoses by GOST 5398-76 depends on the climate where it is used. The hoses operating in regions with tropical climate must be frost-resistant at the temperature of minus 10°С, in regions with moderate climate they must be frost-resistant at the temperature of minus 35°С, in regions with cool climate – at the temperature of minus 50°С, the upper limit – up to plus 90°С.

They are also used in public service (cleaning the storm collector, pumping the flood water from cellars of houses) and in agriculture (sowing complexes, sprayers, etc.).

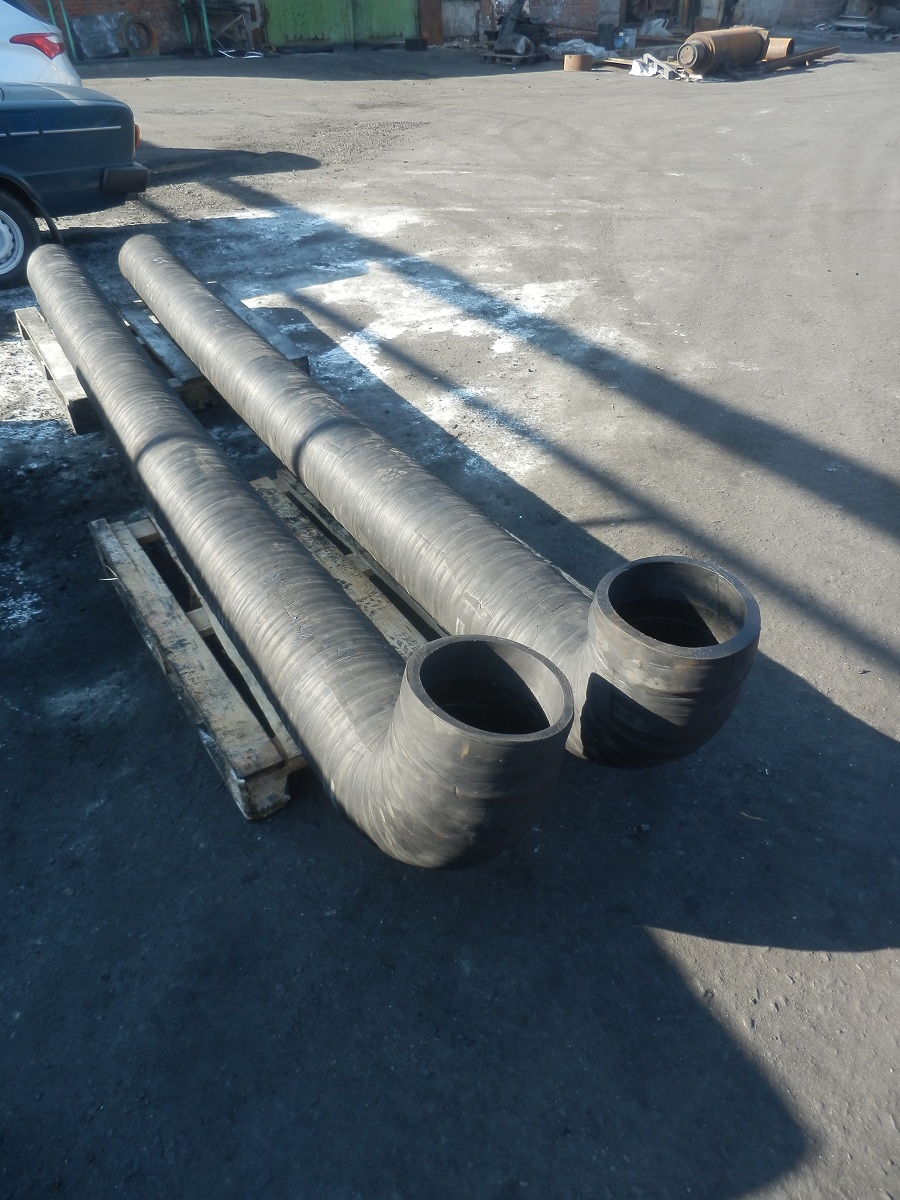

Suction hose is a flexible pipe made of rubber. Every rubber hose, suction hose or pressure-suction hose, is reinforced with textile carcass and a metal spiral. That's why the pipeline becomes solid, preserving the flexibility and elasticity.

Suction hose is a non-reinforced hose made of rubber. Every rubber hose, whether it is suction hose or pressure hose, is equipped with a metal spiral and has a textile body and sealing cups for attaching to armature. Spiral pressure rubber hoses are used for water injection and water suction,fuel oil suction, organic acids suction and suction of other liquids. Some models are suitable for working with gases. Everything depends on the type and class of the products.

Pressure hoses are flexible pipelines made of rubber. Every hose is reinforced with one or few layers of textile. That's why the pipeline becomes more solid and wear-resistant preserving its flexibility.