In seismic regions it is possible to use rubber and metal seismic insulators with lead core, they provide additional damping characters of a bearing during the seismic action. The rubber and metal seismic insulator with lead core has a mark L RSI – Lead Rubber and Metal Seismic Insulator.

Rubber and metal seismic insulators with lead core are used to increase the seismic resistance of bridges and structures. The effectiveness of such bearings is due to high dissipation of energy with lead rod. Such bearing behaves itself as flexible plastic element: it provides seismic insulation and restricts the impact of seismic load to the structure.

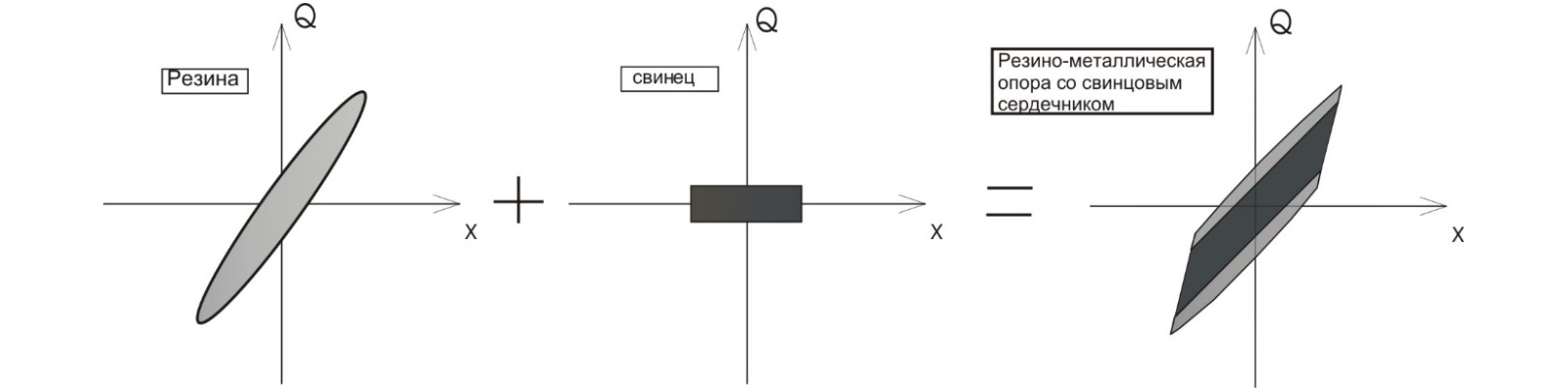

The construction of Lead Rubber and Metal Seismic Insulator and hysteresis curves of rubber bearings without a lead core, the lead itself and with lead core. The presence of the lead core improves the damping characters of bearings.

The principle of seismic insulation is laid in the period of normal vibration displacement (for hard structures, usually, T = 0,3 – 1 second) to the area of a higher period (T = 2 – 3 seconds), that allows to decrease the accelerations that impact to the spans of a bridge during the earthquake. It allows to “isolate” the span of a bridge from the fundament of the structure.

It is reached with the placement of required elastomeric bearings to provide the necessary shifts of fundament and the supports relatively to the span.

The additional decrease of accelerations and decreasing of relative shifts necessary for seismic insulation of the structure is possible by increasing the damping (dissipation of energy).

These two tasks are realized in Lead Rubber and Metal Seismic Insulator. The lead core dissipates the energy when rubber and metal seismic insulator provides shifts and re-centering. The lead core has a character of re-crystallization and preserves its characteristics at unrestricted amount of movement cycle.