Conveying belt or conveyor belt is used in all the scope of production activity whether it is light industry or heavy industry. The conveying belts are used to increase the productivity of the production mechanism of the enterprise by tens of times that will allow to increase the quality of manufactured products and simplify the transportation of the production. Correctly developed and reliable conveyor belt will help to provide the trouble-free operation of the production and it will also add positive changes to the company, in total.

Conveyor belts are produced:

-

Conveyor belt for medium operating conditions

-

Conveyor belt for light operating conditions

Technical characteristics of conveyor belts

The width of conveyor belt varies from 100 to 1600 mm. The length of the conveyor belt up to 200 m (larger length is possible for various types of conveyor belts). The depth of the conveyor belt varies from 3 m to 30 m. Conveying belts are produced on the basis of fabrics of different combined fibers, the solidity varies from 55 N/mm to 100-400N/mm (synthetic high-solid fabrics of Belting of Combined Yarn with Lavsan 65, Technical Nylon 200 and others) for 1-8 gaskets. The unique processing of fabric provides the highest solidity of the structure of belt during its layering.

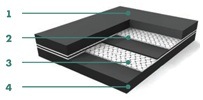

Structure of conveying belts:

-

1- carrying side cover (made of rubber)

-

2- rubber interlayer

-

3- fabric gasket (carcass)

-

4- back cover (made of rubber)

Example of conveying belt marking:

-

2M-1200-5-TN-200-2-6-2-M-RB GOST 20-85

-

2M – belt type

-

1200 – belt width

-

5 – amount of gaskets of the belt

-

TN-200-2 – belt mark, fabric name

-

6 – depth of carrying side (rubber) cover

-

2 – depth of back (rubber) cover

-

M – rubber class (frost-resistant)

-

RB – (rubber) board

Endless rubber belts and ribbed rubber band.

We produce endless belts and rubber bands with straight and chevron ribs for the delivery of granular materials for industrial and agricultural purposes.